Page Contents

Kerf Width Explained

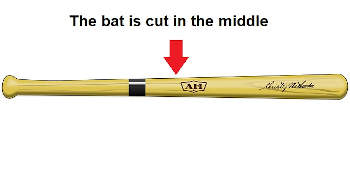

Here’s an example on how to measure for cuts taking the kerf of the blade into account.

Let’s say you have a baseball bat that’s 30 inches long. You want to cut the bat in half, so you end up with a 15-inch barrel (the thick half) and a 15-inch handle (the thin half). You cut the bat in half with your saw. It looks great! You cut the bat right in the middle. Now you have the thin handle and the thicker barrel that are the same length.

Now you measure both to make sure they are both an equal 15” long. But they’re not. Both are a bit shorter than 15” now. Both are the same length of 14- 15/16”- a touch shorter than 15 inches. The reason for this is the kerf of the saw blade was 1/8 of an inch. The kerf is the width of the saw blade and the amount of material removed during a cut.

The saw blade removed 1/8 of an inch of wood when it was making the cut. Divide the 1/8″ in half to determine how much extra wood was removed each half of the bat, that is 1/16″ on each side. That is why both halves of the bat are 14- 15/16 inches and not 15 inches. The saw blade didn’t just cut the bat in half- it removed all the wood in the path of the saw blade. The width of the material removed is called the kerf.

The Basic Explanation of Kerf

To put it simply, the kerf of a saw blade is the widest part of the blade. The widest part of the blade is at the teeth– they stick out slightly more than the rest of the saw blade. Kerf is the amount of material that is removed during a cut. That is always equal to the width of the blade.

Thin Kerf or Full Kerf?

Saw blades generally fall into two categories- full kerf (FK) and thin kerf (TK). On a 10” saw blade, almost all thin kerf blades will be 3/32”, and full kerf blades will be 1/8”. A difference of 1/32 of an inch. You might say to yourself that 1/32” is not that much of a difference between the two. It might not look like that much, but a full kerf blade is 33% thicker than a thin kerf. Keep in mind that there are no industry standards for thin kerf and full kerf. A thin kerf from one company could be almost as wide as a full kerf from another. But most major manufacturer’s follow 3/32″ for TK and 1/8″ for FK.

There are also ultra-thin kerf blades (UTK) primarily used in industrial settings. You’re probably not going to see these in most places outside of a woodworking factory.

Advantages and Disadvantages of Thin Kerf

A thinner kerf cuts through material more efficiently than full kerf, and it uses less power to do so. If your saw is on the lower end of the power spectrum, it becomes beneficial to use a thin kerf blade. However, when using a low-powered saw and a full kerf blade, you can make the cut slower to compensate for the larger and heavier blade of a full kerf. But you risk burning the wood due to increased friction and longer time the blade is in contact with the workpiece.

Thin kerf blades are more prone to deflect when making cuts versus a full kerf blade. Deflection is when the blade bends while passing through a material. A knot in the middle of a piece of wood could cause deflectiont. Deflection will cause your cut to not be perfectly straight even though it might look straight to the naked eye.

The round metal plate on a thin kerf blade is thinner than its full kerf counterpart, making it more prone to bending and deflection. It’s not something to be overly concerned about if you’re using quality blades. A high-quality thin kerf blade will not deflect nearly as much as a lower quality blade, and will even rival some full kerf blades.

Advantages and Disadvantages of Full Kerf

A full kerf blade will be more stable than a thin kerf. The circular metal plate is thicker, giving it more mass and higher stability. The increased mass makes it more difficult for the saw to spin due to its heavier weight. This makes it better suited for a high-powered saw. A full kerf blade will also be less affected by heat when making a cut. It can disperse heat more efficiently due of its thicker metal plate. The thicker plate makes it less likely to bend while passing through the material, decreasing the chances of blade deflection.

Full kerf will also produce more sawdust while removing more material than a thin kerf. Removing 1/32” more material is probably not a big deal for you. Although, that tiny amount can add up to a good sum of money when cutting expensive woods.

So which is better?

It’s not possible to say one is better than the other. Thin kerf and full kerfblades each have their pros and cons. Choosing which one to use will depend on different factors- the saw, the material being cut, the type of cut being made, etc.

Is your saw blade not cutting like it used to? Prefer a cleaner cut over a rough one? Check your blade for sharpness and read some tips on how to prevent tearout on your cuts.