Using the right saw blade is like having the right set of tires on your car. If you’re driving a Corvette, you want to have high-performance tires on the car. You want to take turns hard, and go fast. That fits the purpose of a sports car. Performance is what you’re looking for. If you live in Minnesota, you want snow tires on your car in the winter. You want a better grip on the road when it snows and gets slippery. Traction in bad conditions is your goal on snowy roads. Here are some tips for picking saw blades that will help you choose which is right for you.

Just like cars and tires, all saw blades are not created equal. You get what you pay for when it comes to saw blades, and all tools in general. Better saw blades use better materials. Better steel, better manufacturing, better quality control are all things you are paying for. You also have to take the kerf of the blade, and the tooth design into consideration when you put the blade to work. Both of which affect the quality of the blade and the quality of the cut it will make.

Page Contents

High-Quality Blades and Bargain Blades

You don’t have to spend a lot of money to get a good saw blade. But, you’re giving yourself a much better chance if you do. When you opt for a higher quality blade, you don’t have to worry about getting the bad blade from the batch. Spending a little extra on a quality blade can save you some money in the long run. A better blade will last longer, cut more predictably, and can be sharpened more times than a budget blade. That’s if it’s worth it to resharpen a bargain blade at all.

While it pays to spend more for a higher quality blade, it’s just as important to choose the right blade for your project. Just like your car, you’re not going to want winter tires to drive your Corvette to race at the track. You won’t receive the best results using a ripping blade to make a cross cut.

The Basics of Saw Blades

Let’s say we have 2 blades from the same manufacturer. Every specification is the same except for the number of teeth. The teeth are what do the cutting on the blade. The more teeth you have on the saw blade, the cleaner and smoother the cut will be- in most cases.

The Effects of Heat on a Saw Blade

OK, that sounds great, so let’s just get the saw blade with the most teeth you might be saying. Well, the downside is that the more teeth you have, the longer it takes to cut through the workpiece. The longer it takes to make a cut means more friction from the blade, which means more heat. Heat increases the possibility of burning the wood, or whatever material your working with. It will also distort the shape of the blade through expansion. Heat makes things expand, and will make your saw blade expand as it heats up. This affects the quality of the cut.

High Tooth Count Blades

You sometimes have to deal with the risks of using a high tooth count blade if your project needs clean, smooth finished cuts. If you’re building a coffee table for your living room, you want the cuts to be clean and smooth. When you’re done, the coffee table will look good because the cuts are sharp and finely finished. For a project like this, a crosscut blade would be ideal.

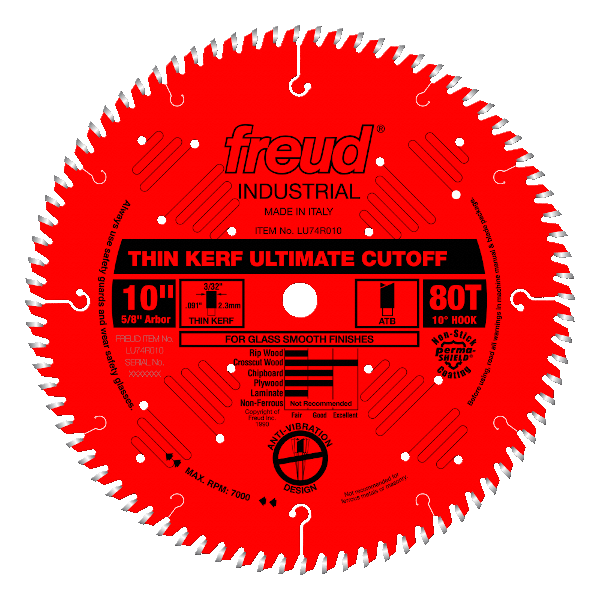

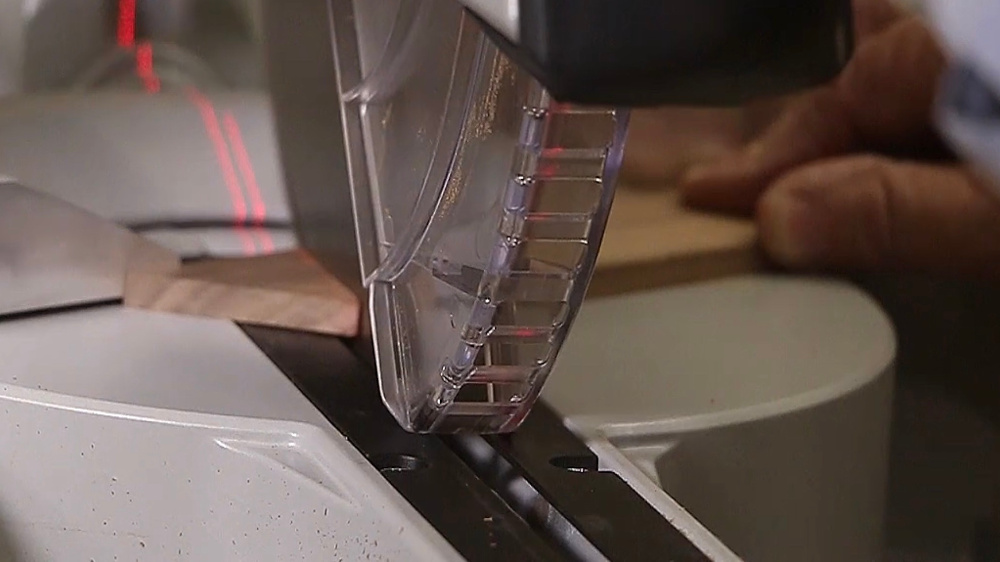

Manufacturers of high-quality blades include ways to mitigate the effects of heat. They use features like expansion slots to minimize blade expansion (see picture on right). Heat is also affected by the kerf of the blade. A full kerf blade will generate more heat than a thin kerf.

Maybe Looks Don’t Matter

If you’re building a set of wooden sawhorses, you’re not concerned with clean cuts. You don’t care too much about what it looks like in the end. You’re more concerned with them functioning correctly. You would be better off using a saw blade with a lower number of teeth. A ripping or general purpose blade with a low tooth count will work better. Those blades will cut quicker and in turn, last longer. Using a high tooth count crosscut blade here would just wear it out quicker.

Blade Selection Tips

One of the first decisions you should make is: what are your plans? If you plan on doing a lot of cutting with different woods, and you have varying needs on finish quality, then you should go with different saw blades like a dedicated ripping blade, and a dedicated crosscut blade.

On the other hand, if you’re not interested in investing in a many specialty blades, you can opt for a good general purpose blade. A general purpose blade will not be great at any one specific thing. Instead, it will be good at a bunch of different cuts.

Just because one blade is better at one aspect of cutting doesn’t mean it’s a better option overall. Consider all the factors before deciding on a saw blade. There’s always the right tool for the right job, the wrong tool, and the good enough option.

So what saw blade should I get?

Pairing a Rip Blade with a Crosscut Blade

If you decide you want both rip and crosscut blades, you should accept that each one of the specialty blades will be great at its intended purpose. But they will be less than great for all other cuts. The upside is that you get optimal results, and the blades will stay sharper for a longer period because they share in the workload. The downside is the initial cost being higher.

Tips for Picking General Purpose Saw Blades

Let’s say you want to go with a general purpose blade. It will never make as clean of a cut as a crosscut blade, but it might make a cut that’s good enough for you. On the other hand, the general purpose blade will leave a much cleaner cut than a rip blade. There are all kinds of trade-offs when using a general purpose blade, but that doesn’t mean that it’s not the right blade for the job. It just might not be the best blade for the job.

If you’re a perfectionist and you just want the best performance, you will go with task-specific blades- a ripping blade, and a crosscut blade to start. If you’re not sure exactly what type of blades you need yet, a good general purpose should get the job done to start. Just make sure you’re getting quality blades if your budget allows.

Tips for Picking Crosscut Saw Blades

Crosscut blades are designed to cut across the grain of the wood. Specifically, across both hard and soft planks of wood. They have high tooth counts to make smooth, clean cuts. However, that makes them more likely to burn the wood. Burning is a serious concern when cutting thicker wood.

Crosscut blades have high tooth counts, but tooth count is relative to the size of the blade. A high tooth count 7 ¼” crosscut blade will have about the same number of teeth as a 12” ripping blade. A 12″ ripping blade will have fewer teeth than a 12″ crosscut. Having more teeth means having a cleaner cut, but it also leads to higher friction and heat.

A 60 tooth to 80 tooth blade is the most effective out of the crosscut blades at a 10 inch blade diameter. 100 tooth blades don’t have that much of an advantage over 60T and 80T given the increased heat and slower cut speed. They do have their niche though. 100T is optimized for thin plywood and veneers because of its fragile nature.

Tips for Picking Ripping Saw Blades

Rip blades are the opposite of crosscut blades. These blades are designed to cut through wood quickly, along the grain. To achieve that purpose, they have lower tooth counts (10T- 24T) than crosscut and general purpose blades of the same size. The lower tooth counts puts less stress on your saw while cutting. However, the cut will not be as clean, and there usually will be a good amount of tearout.

Some manufacturers make ripping blades that will finish with a glue ready edge. They’re more designed to rip thinner materials and usually have a tooth count of 30T and up. Ripping blades are common table saw blades- read our tips for preventing kickback while using a table saw.